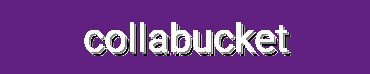

- Structure Stabilit: Stability is enhanced with a new steel HSS frame. Each axis features two16mm Steel HSS linear tubes , lead screw motion drivers, dual Y-axis rails, and a all metal frame. The Z-axis utilizes linear rails instead of rods and T8 lead screws.

- Upgraded Control Box and Mainboard: The upgraded control box features essential functions like emergency stop and home buttons. Its metal casing is dust-proof and easy to maintain. It includes a powerful and quiet Toshiba TB6S109 driver with a 32-bit chip, along with multifunctional ports for air assist pump and MPG.

- Compatibility Upgrade: The 4040-PRO CNC machine is supplied with 42mm and 52mm spindle mounts, compatible with original spindles, 300W spindles, and our laser module. Additional 65mm (B0BRZSY475) and 69mm (B0BRZSVVK3) spindle mounts are also available for separate purchase.

- Various Upgrade Accessories: Supports a 4th axis rotary module kit(B0C581H2B3), allowing the 4040-PRO CNC to carve from various angles or perform full 3D rotary carving with the right software. Enables a Wi-Fi module(B0DK54JHS6) for mobile control. Also you can upgrade the XZ-axis(B0DHGN4ZYH), strengthen the screw material, and improve stability and speed.

- Easy Assembly: Main parts are pre-assembled, enabling setup in about 15 minutes. The spoilboard consists of two replaceable MDF boards, so you only need to swap the damaged one instead of the entire spoilboard.

- Large Working Area: The working area of 15.7” x 15.7” x 3.1” is sufficient for daily wood carving. The redesigned Z-axis carriage simplifies spindle swapping, while additional screw holes allow for higher installation of larger spindles, increasing overfeed height.